Views: 5 Author: Site Editor Publish Time: 2024-08-09 Origin: Site

The treatment of oily wastewater is currently a hot issue in environmental protection, with a global extraction of 54 billion cubic meters of oily wastewater in 2020. In order to treat oily wastewater, various adsorption technologies have also been developed, but there are still problems such as the use of a large number of chemical reagents, limited installation space, and low oil droplet separation efficiency. Ceramic membrane is one of the most promising methods for oily wastewater treatment, especially for oil/water (O/W) lotion separation with oil drop size greater than 20um.

Ceramic membranes are mainly made of metal oxides sintered at high temperatures, with high mechanical strength, chemical and thermal stability, and abundant hydroxyl groups on the surface, making them particularly suitable for oily wastewater treatment. For the treatment of oily wastewater, large oil droplets may accumulate on the membrane surface to form a filter cake layer, while small oil droplets may block the membrane pore size. Therefore, membrane fouling is an inevitable phenomenon in the separation process of oily wastewater. Therefore, in order to control membrane fouling, it is necessary to regularly and repeatedly rinse and remove pollutants. When the performance of the membrane decreases by 50% -60%, chemical cleaning is required to remove irreversible dirt and restore the performance of the membrane. However, after such frequent chemical cleaning, the service life of the membrane will also decrease, and ultimately it will inevitably be replaced, leading to an increase in sewage treatment costs.

Traditional ceramic membranes have significant separation effects on oily wastewater, but they also have their own shortcomings that are difficult to overcome, such as large average pore size, low filtration accuracy, and easy pollution, which cannot continuously and efficiently filter ions and small molecule pollutants. To solve the problem of membrane fouling, a common strategy is to construct an anti fouling membrane surface by changing the surface physicochemical properties of the membrane, in order to reduce the interaction between oil droplets and the membrane surface. Simply put, it refers to the functionalization of ceramic membranes to address some of the problems encountered by traditional ceramic membranes, in order to enhance filtration accuracy, improve filtration efficiency, and increase service life.

Ceramic membranes are classified into active and passive types based on their anti fouling mechanisms. Active anti pollution ceramic membranes can reduce pollution by coating a hydrophilic or charged layer on the membrane surface, while passive anti pollution ceramic membranes typically require the help of chemical substances (such as H2O2) or external energy (such as electricity, ultraviolet radiation) to resist pollution.

Active anti fouling ceramic membranes modified with TiO2, ZrO2, and Fe2O3 exhibit lower fouling properties. These metal oxides can improve surface hydrophilicity and generate surfaces with lower negative charges, thus repelling oil droplets from the membrane surface. GO modified ceramic membranes can simultaneously improve permeation flux, oil retention rate, and pollution resistance, making them a research hotspot for hydrophilic surface modification of membranes. Passive anti fouling ceramic membranes, such as photocatalytic and charged membranes, can prevent oil droplets from depositing on the surface of these membranes through charge conversion or degradation by free radicals or in-situ generated ultrasonic waves. In addition, they exhibit unique advantages in ceramic membrane modification, but have a short service life, high cost, and are difficult to use on a large scale.

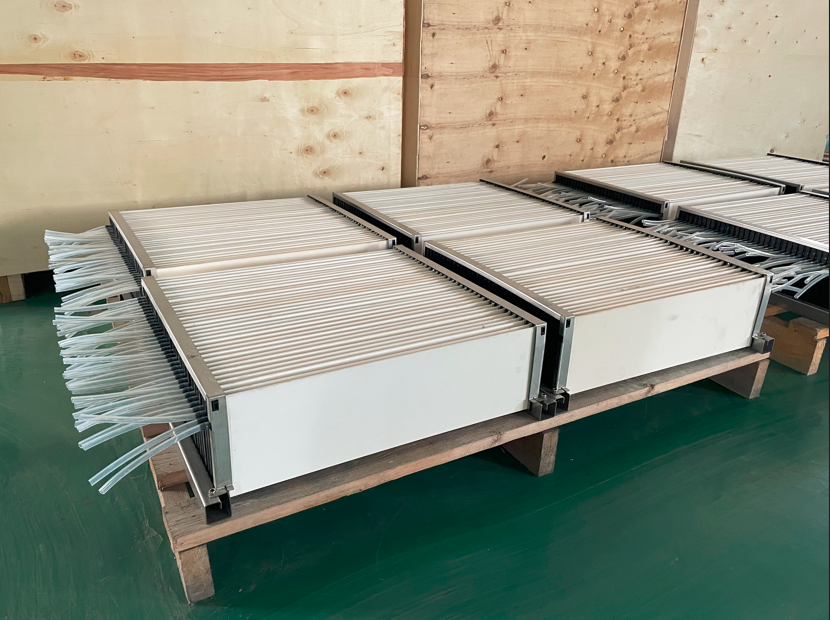

NanoMem® is a high-tech enterprise integrating R&D, production and service of plate ceramic filtration membrane products. We are professional supplier of flat ceramic filtration membrane, plate ceramic filtration membrane unit and MBR system. If you are interested in our products, please contact us at 0086 512 6638 9461 and email: export01@szdasen.com.