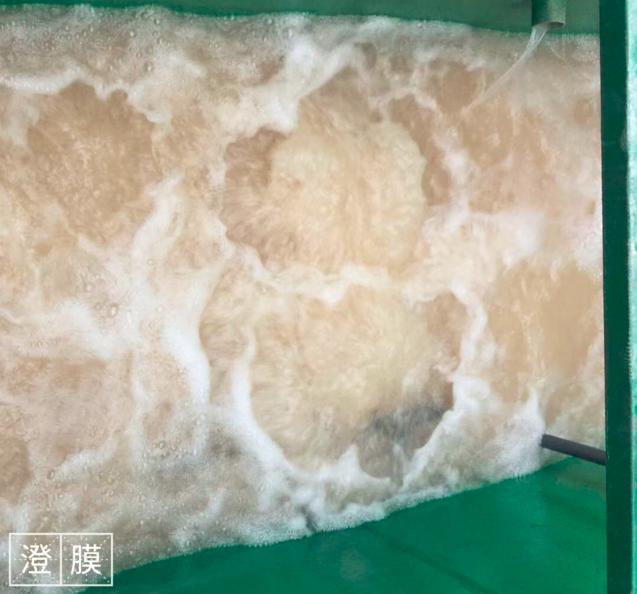

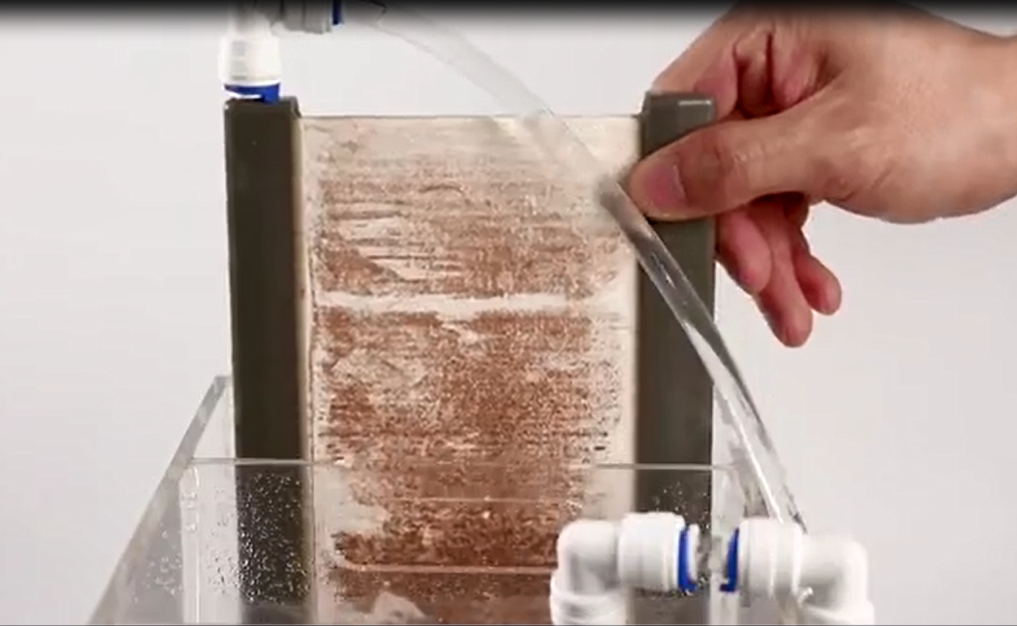

2024-10-31 Using flat ceramic membrane to treat oil production wastewater, the SS and oil content in the effluent are both less than 1mg/L, and the effluent quality is better than the Al level standard for oilfield reinjection water quality. The optimal conditions for treating oily wastewater using flat ceramic membrane are: optimal aeration rate of 2.0mL/min; The optimal membrane flux is 22.5L/(m2.h), and the operating temperature is 50 ℃. The optimal baffle position is the 2nd baffle. The above experiments and results indicate that the use of flat ceramic membrane to treat oily wastewater can achieve long-term stable operation, and the effluent can fully meet relevant standards. It can be used for the effective long-term operation of low utilization ceramic flat membrane treatment of oily wastewater, and the effluent can be used for the reinjection of low-permeability permeable layers, with good development prospects.

Read More

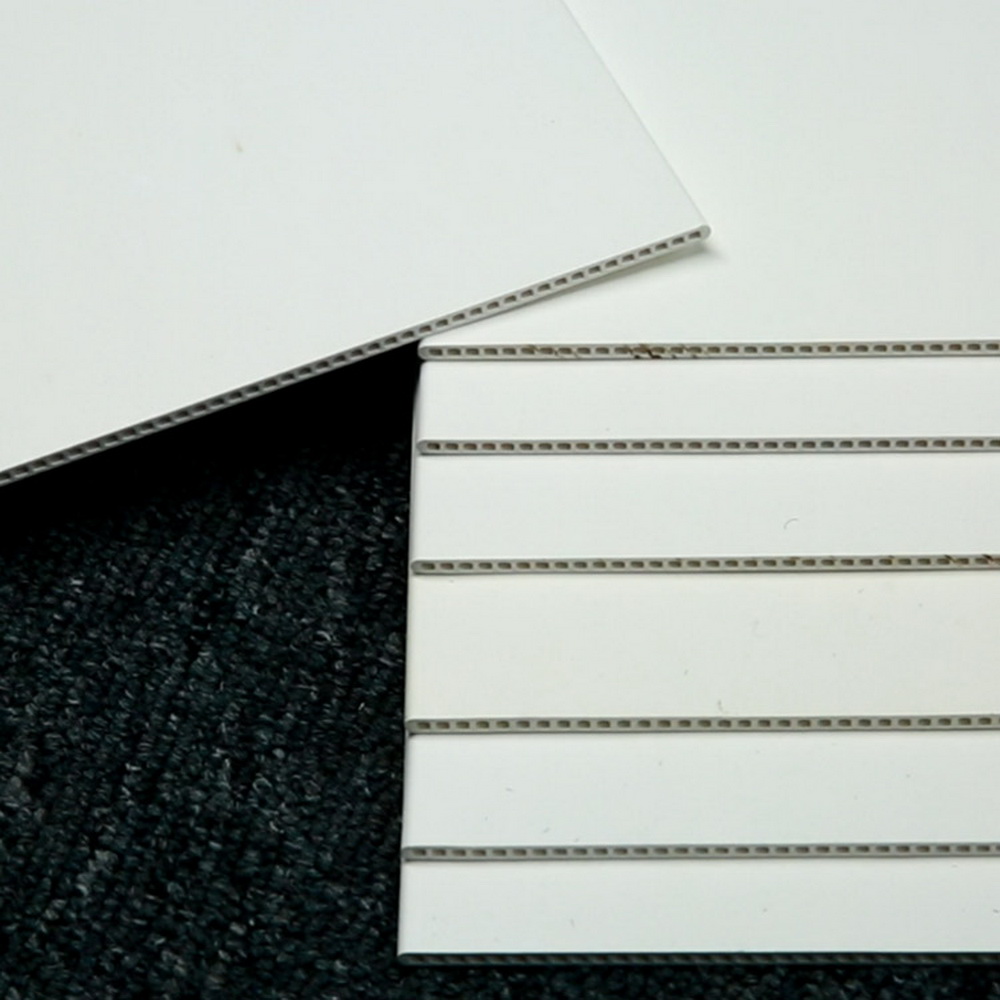

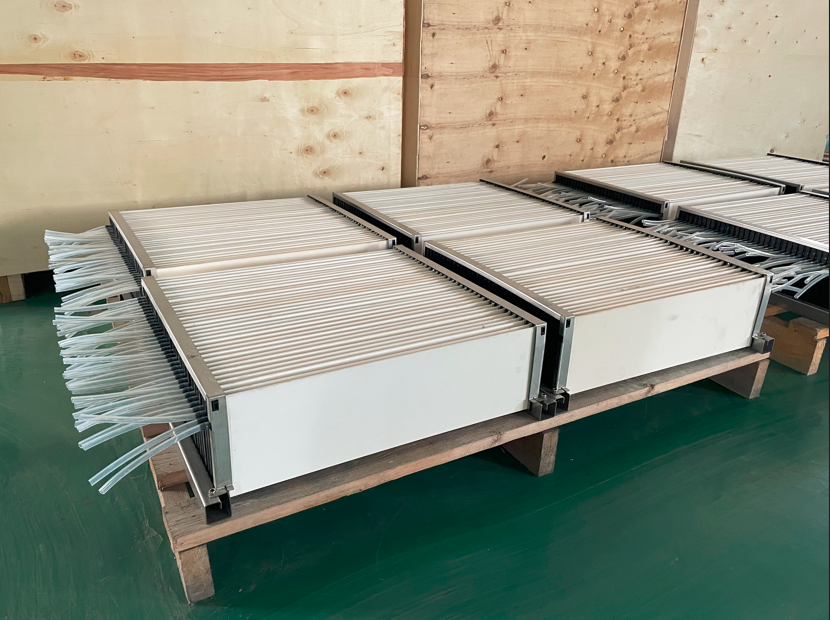

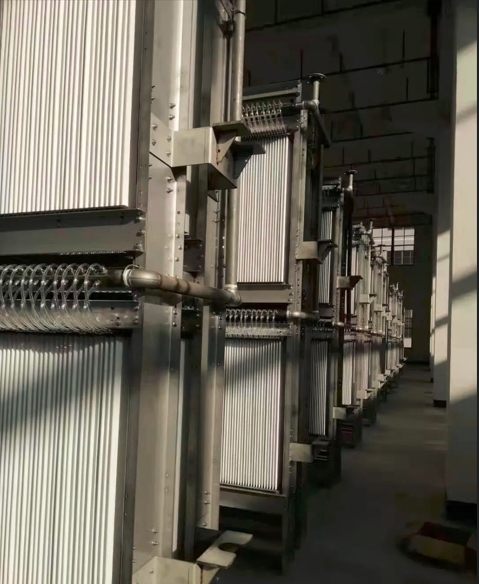

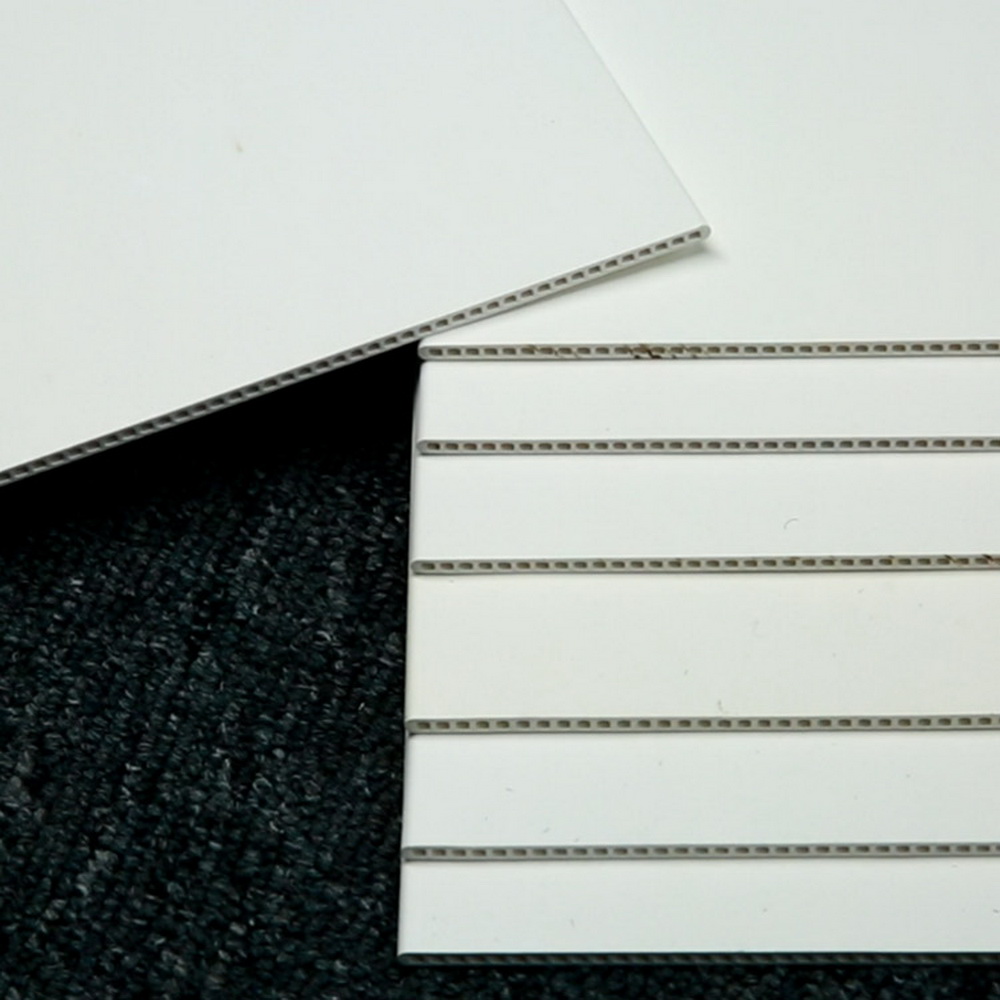

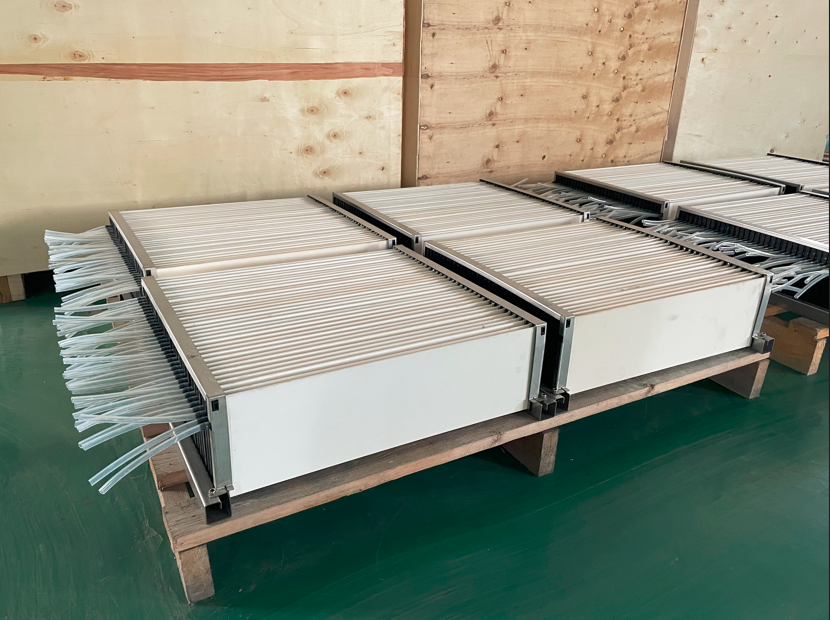

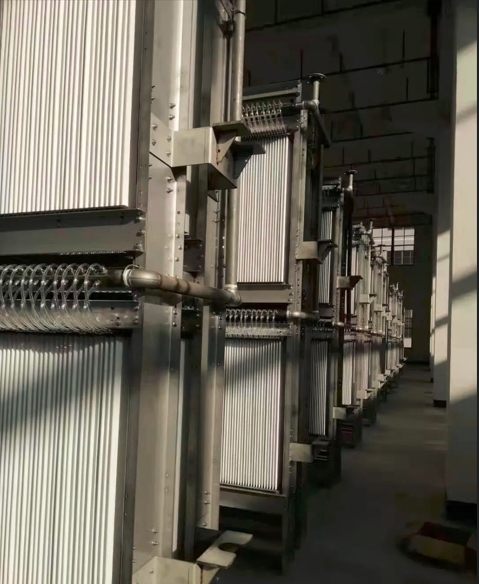

2024-10-17 Flat ceramic membrane is a common component in membrane separation technology, which has a wide range of applications in various fields due to its special material properties and structural design.

Read More

2024-09-26 In the field of municipal water supply, ceramic membrane technology has been proven to operate stably for a long time, with high effluent quality and not affected by fluctuations in raw water quality. For example, in Japan, over 118 water plants have applied ceramic membrane technology, with the largest plant having a daily processing capacity of 170000 tons and 30 years of successful operation experience. The Caicuo Port Water Plant in Singapore also adopts ceramic membrane technology, with a scale of up to 180000 tons per day. These cases demonstrate that ceramic membranes not only provide high-quality drinking water, but also maintain stability and efficiency in large-scale applications.

Read More

2024-08-16 Coal accounts for over 70% of China's energy structure, and during the coal mining process, a large amount of wastewater is discharged. If discharged directly without treatment, it will inevitably cause serious pollution to the environment and result in a significant waste of water resources. Theref

Read More

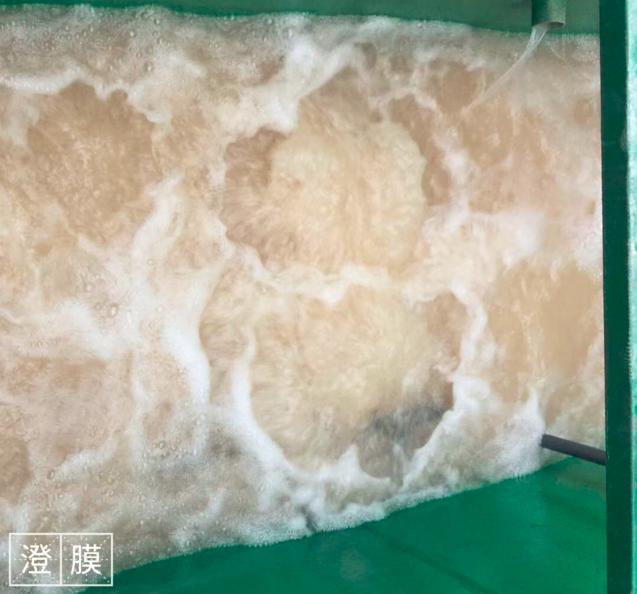

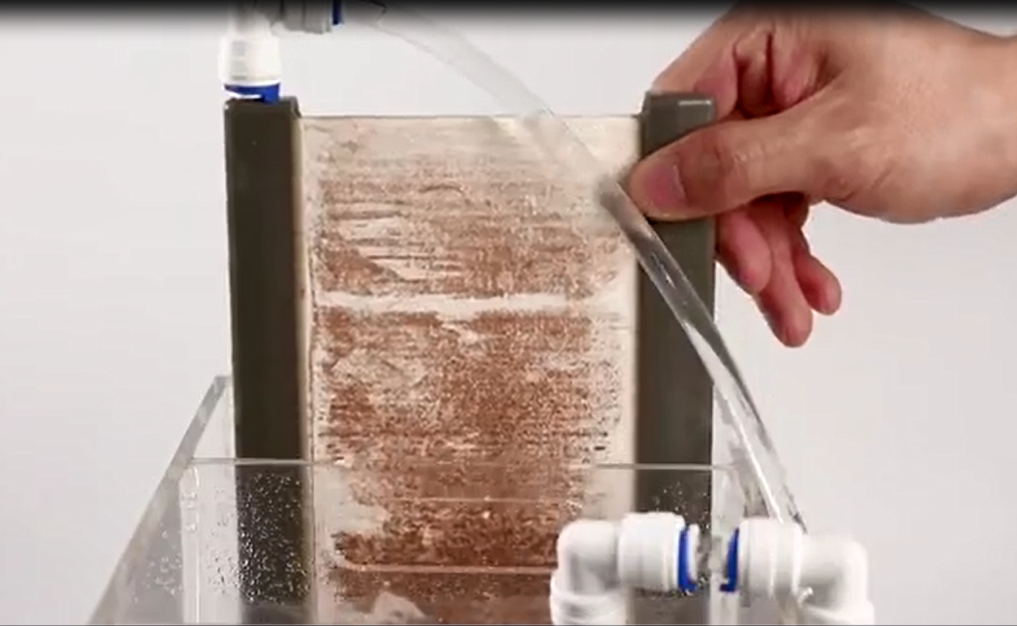

2024-07-19 Ceramic membrane separation is an advanced technology that can be widely used for impurity separation and product purification in fields such as chemical engineering, food, medicine, and environmental protection. However, pollution and blockage may occur during its use, leading to a gradual decrease in membrane permeation flux, especially in ceramic membranes used in wastewater treatment, where fouling and blockage can occur at any time. How should we deal with the problem of ceramic membrane "fouling"?

Read More